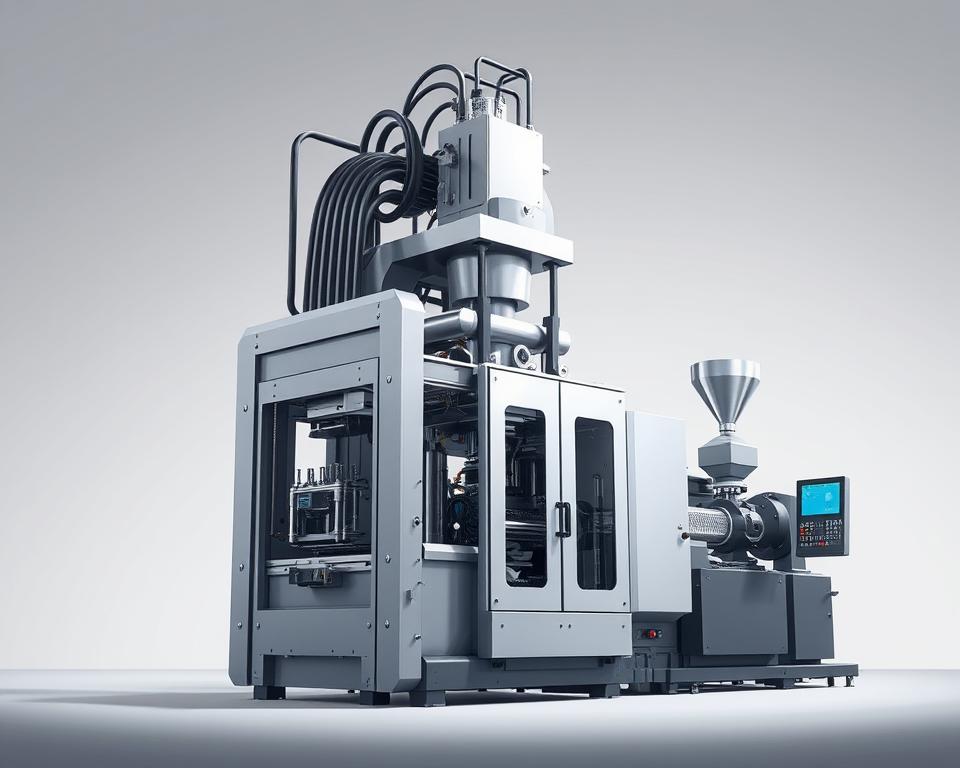

Guide to Engaging China Injection Molding Suppliers

The important meeting has recently finished, your new project has the green light, the timeline is aggressive, and funding is, to put it mildly, limited. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

Naturally, you agree. It seems sensible at first glance. The potential savings can be massive. But your mind is already racing. You know the rumors, don’t you? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It feels like walking a thin line between big savings and total project failure.

But here’s the catch. Sourcing plastic mold can be a calculated project. It’s simply another project with clear steps. And as with any project, success depends on your methodology. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Disregard those scary tales. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. Don’t assume a remote factory can guess your needs. It’s akin to asking someone to price-build “a structure” with no details. The responses you get will be all over the map, and none of them will be useful.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This package is your project’s foundation.

So, what goes in it?

Begin with 3D CAD models. They cannot be skipped. Use standard formats such as STEP or IGS to ensure compatibility. This is the master blueprint for your part’s geometry.

However, 3D alone won’t cut it. Include precise 2D engineering drawings. This is where you call out the stuff that a 3D model can’t communicate. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

After that, material choice. Don’t label it simply “Plastic.” Nor just “ABS.” Be specific. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. What’s the reason? Because plastic grades vary by the thousands. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with what is plastic mold.

Your supplier might propose substitutes, but you must set the baseline.

Don’t forget the commercial info. What’s your forecasted annual volume (EAU)? You must specify if it’s a 1K-part tool or a 1M-part production run. Cavity count, tooling cost, and per-unit pricing depend on volume.

Hunting for the Best Supplier

With your RFQ perfected, who gets your RFQ? The internet has made the world smaller, but it’s also made it a lot noisier. It’s easy to find a supplier; it’s hard to find a good one.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They offer breadth but not depth. But think of them as a starting point, not the finish line. Narrow your pool to about a dozen promising firms.

Still, you must dig deeper. Consider using a sourcing agent. They do cost extra. But a reputable agent brings pre-screened factories. They bridge language and cultural gaps. For a first-time project, this can be an invaluable safety net. It’s schedule protection.

Also consider trade fairs. If you can attend, shows such as Chinaplas transform sourcing. Meeting onsite is unbeatable. Hold samples, talk shop, and gauge professionalism firsthand. Also, leverage the tried-and-true referral network. Consult trusted colleagues. Peer endorsements carry huge weight.

Shortlisting Serious Suppliers

After firing off that RFQ to a broad pool, the quotes will start trickling in. Some prices will undercut logic, others will shock you. Your task is to filter them down to 2–3 credible finalists.

How to proceed? It involves both metrics and gut feel.

Step one: audit communication. Do they respond quickly and clearly? Do they communicate effectively in English? The true litmus: are they raising smart queries? A great supplier will review your RFQ and come back with thoughts. For instance: “Draft angle here could improve mold release. Tolerance check via CMM adds cost—proceed?” Consider that a big green light. It proves their expertise and involvement. A supplier who just says “No problem” to everything is a walking red flag.

Next, dig into their technical capabilities. Get their tooling inventory. Review examples of parts akin to your design. A small-gear shop won’t cut it for a big housing.

Finally, inspect the factory. Skipping this is a mistake. Just as you interview hires, audit suppliers. You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They dispatch an on-site auditor for a day. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. That small investment can save you thousands.

From Digital File to Physical Part

You’ve selected your partner. you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Now the process kicks off.

Your supplier’s first deliverable is a DFM analysis. DFM stands for Design for Manufacturability. It’s the engineering critique for moldability. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. Comprehensive DFM equals a top-tier supplier. It becomes a joint effort. You iterate with their team to optimize the mold.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. Weeks on, you receive the thrilling “T1 samples shipped” notification. These represent the first trial parts. They are your moment of truth.

Be prepared: T1 samples are almost never perfect. This is normal! Look for small flaws, slight size errors, or surface marks. You critique, they refine, and T2 plastic mold parts arrive. It could require several iterations. Build buffer time for sample iterations.

At last, you get the perfect shot. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is now the benchmark sample. You ratify it, and it becomes the quality yardstick for production.

Completing the Sourcing Journey

Receiving the golden sample seems like victory, but you’re not done. Next up: mass manufacturing. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. This often involves a pre-shipment inspection. Use a third-party inspector again. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. They’ll send you a detailed report with photos and measurements. After your approval, you release the shipment and final funds. This audit shields you from mass defects.

Don’t forget shipping details. Know your shipping terms. Are you on FOB terms, where they load and you take over? Or EXW, where you handle everything from their gate? Your Incoterm selection drives landed expenses.

Overseas sourcing is a marathon. It relies on partnership-building. See them as collaborators, not vendors. Open dialogue, trust, and rigorous procedure deliver results. It’s a challenging project, no doubt. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re ready.